GENERAL DESCRIPTION

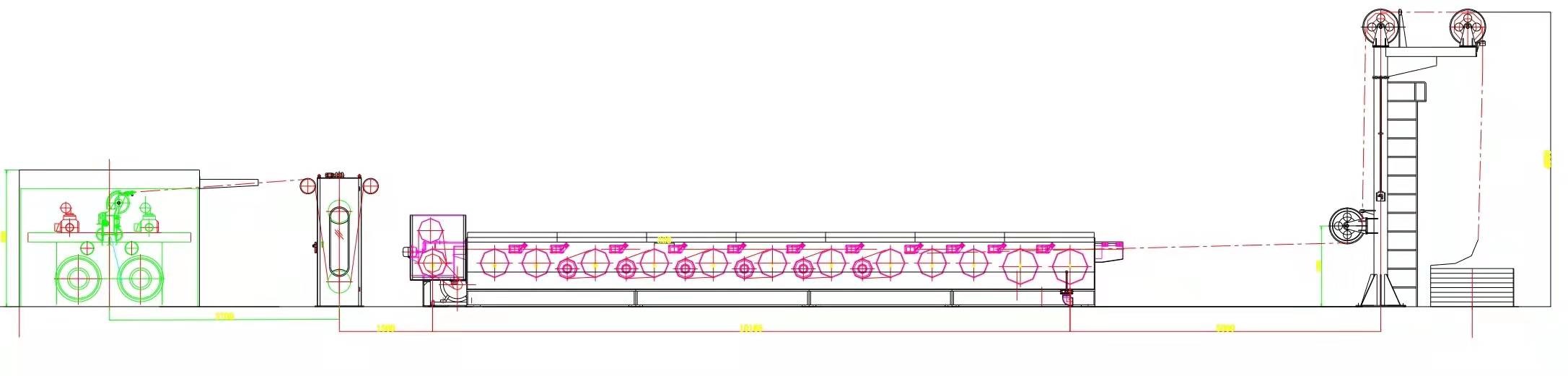

This machine is used to draw Ø2.2- Ø4.5mm aluminum Alloy wires or same sector shaped wires(S,Z,C,T and other shape) from Ø9.5mm aluminum alloy rod. To draw Ø1.8- Ø5.0mm aluminum wires or same sector shaped wires(S,Z,C,T and other shape) from Ø9.5mm (12mm) aluminum rod.

MAIN CAPABILITY CHARACTERISTIC

- The drawing blocks rank in a horizontal row, and the cantilevers of all die holders are short and in equal length.

- The surface of drawing blocks is coated with tungsten carbide power, which is strong in hardness and wear proof, having long life span.

- Main drawing machine and dead-block are driven separately, and all the dies can be changed conveniently and easily.

- Continuous dual take up, automatic reel-change, the automatic reel-change can be done at more than 99% efficiency.

- Driven by DC motor, the imported PLC and touch screen (Siemens or Pro-face), which is convenient for the operator to set and display the parameter on the touch screen.

TECHNICAL PARAMETER

| Inlet wire diameter | Ø9.5mm(12.0mm) Aluminum Ø9.5mm Aluminum Alloy |

| Outlet wire diameter | Ø2.0- Ø4.5mm Al Alloy or (S,Z,C,T and other shape 5-25 mm2) Ø1.8- Ø5.0mm Al or (S,Z,C,T and other shape 5-25 mm2 ) |

| Max drawing speed | 25m/s for round wire 10-16m/s for (S,Z,C,T and other shape) |

| Drawing capstan diameter | Ø450mm |

| Max. drawing dies/ capstans | 13 |

| Die dimension | Ø45mm×25mm |

| Capacity of the accumulator | 7m |

| Dual-bobbin take up size | PND500~PND630 |

| Main motor power | 30KW (AC)X13 |

| Power of motor for constant speed wheel | 55KW (AC) |

| Power of motor for dual-bobbin take up | 30 KW×2 (AC ) |

| Total power | 520KVA(running 60%) |

| Machine dimension(L×W×H) | 25000×5000×4800mm |

Рус

Рус